Earlier rear engined VW models (Beetles, split screen / T1 buses and bay window / T2 / T2a / T2b buses didn’t have rev counters (also known as tachometers or tachos) as standard. They were available as an option in some models, and became standard in some higher spec, later model T25 / T3 / Vanaon models. All of the VW rev counters in these models were electronic, made by VDO, and driven from the coil negative terminal (petrol / gasoline models), or the alternator ‘W’ terminal in diesel models.

How all the types of rev counter and rev counter signal involved in Subaru powered VW conversions work:

All designs of rev counters (also known as a tachos or tachometers) used in rear engined VW models were electronic – i.e. they never used mechanical rev counters as some other makes. They were driven by either:

1. The coil negative terminal , where the points connect. This was used in petrol / gasoline models.

2. A dedicated terminal on the alternator (usually marked ‘W’). This was always used on VW diesels (some other makes also used the alternator W terminal to drive the rev counter on petrol models too, but not VW).

……….as these were the only sources of electrical engine speed information.

Electronic rev counter technology of the time (typically discrete analogue, or in VDO’s case, very early bespoke IC’s (from about 1968 onwards) meant they only worked with the one type of signal that they were intended for. I.e. you couldn’t swap a diesel rev counter for a petrol one or vice versa. This includes the types used all rear engined VW models as standard, and many available as aftermarket accessory rev counters until around the mid 1990’s. From the mid 1990’s onwards (so aftermarket only for rear engined VW’s, or at least the models not built in South Africa of South America), newer designs became more flexible in terms of what input signals they could accept. Some had multiple input input connections, so you had to select the right one, but better designs (typically later ones, using newer technology) could accept multiple input signal types on the same input – automatic filtering out the any unnecessary / harmful parts of the final, leaving just what is needed.

Rev counter signal types:

- The signal from the coil negative terminal on all rear engined VW petrol models is a 12V square wave with a massive superimposed spike each time the points close. This spike is typically many hundreds of volts.

- The signal from the alternator ‘W’ terminal on the diesel model is a sine wave of variable frequency and voltage.

In both cases the frequency is the important part of the signal in terms of what the rev counter needs to know, as it represents engine speed. With the alternator W signal terminal, the other information the signal includes (the voltage of the signal increasing as rpm increases, and the fact that the signal is an AC sine wave is filtered out or just ignored by the signal conditioning circuitry in the rev counter, which is typically only looking for each time the AC voltage crosses zero – i.e. using a zero crossing detector circuit to isolate the frequency information. With the coil negative terminal signal in petrols, there are two approaches. In both, the high voltage spike has to be removed, so it does not damage the other circuit components. With one method, the whole signal is scaled down. This reduces the 12V square wave part of the signal to being insignificant, and measures the frequency of the scaled down voltage spike to drive the rev counter. This results in a circuit which cannot be driven by a 12V square wave, as is the case with the VW petrol rev counters. The second method removes the high voltage spike (typically by using TVS diodes, etc), and using the resulting ‘clean’ 12V square wave to drive the rev counter, so typically works from other 12V square wave sources such as dedicated ECU outputs.

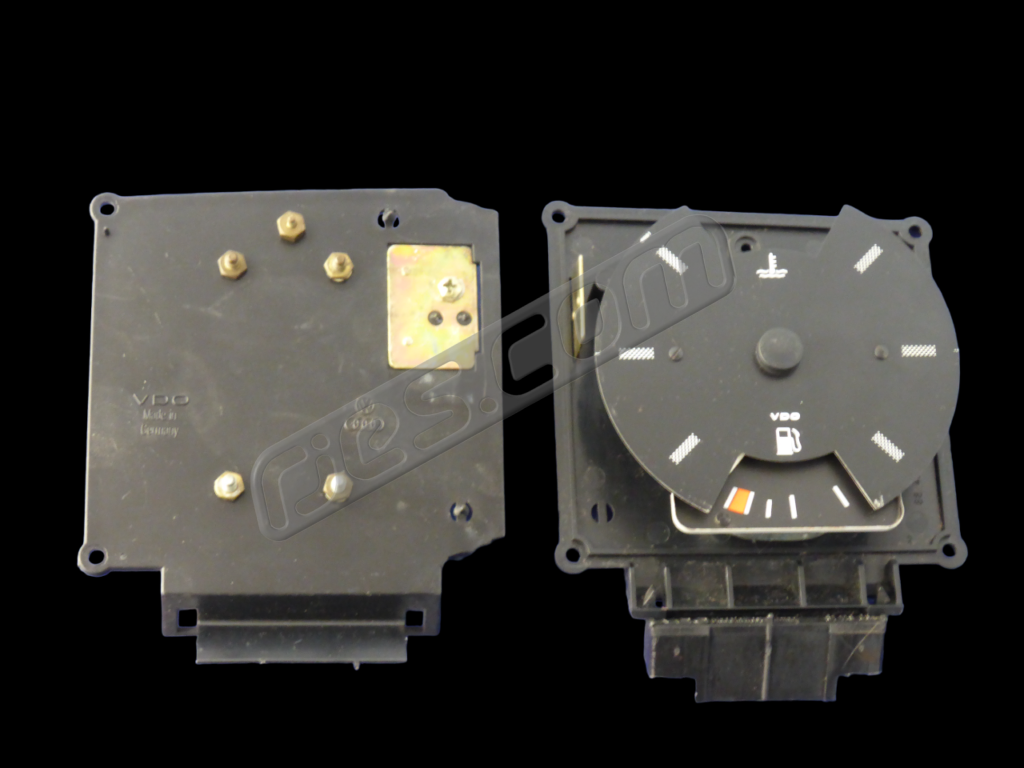

On pretty much all engine management systems prior to the introduction of network systems such as CAN bus, both petrol and electronically managed diesel, the rev counter was typically driven directly by a dedicated output from the ECU. This covers all of the pre CAN bus Subaru models. With this system the signal is a clean 12V square wave (i.e. no superimposed spike of hundreds of volts). This is not compatible with of the rev counter types used in rear engined VW’s or the aftermarket VDO models which were clamped into the panel with two nuts and a U shaped bracket, as they scale the whole signal down so require the presence of the high voltage spike on the signal.

Later VDO aftermarket models (from around the mid 1990’s onwards) were clamped into the panel with a large plastic nut which screws onto a thread around the rear case outer diameter are more versatile in terms of what input signals they accept. They typically work from a 12V square wave, a 12V square wave with superimposed high voltage spikes or an alternator W terminal.

What rev counter should I buy to fit into my Subaru powered VW?

If there is an original VW rev counter for your model, it will most likely look better, maybe fit better, and maybe be better quality than many of the aftermarket options. If it was originally intended for a petrol application, it won’t work from with the signal from a Subaru ECU, but this can very easily be solved by fitting one of our rev counter interfaces between the ECU and rev counter (no modifications ot the rev counter of the ECU required).

If there is no original VW rev counter for your application, or they’re too expensive, or if you just prefer an aftermarket one, you should used one intended for a petrol application. You have two choices of how to drive it from the dedicated Subaru ECU signal. For the installation to be as simple as possible, make sure the model you choose is compatible with a 12V square wave signal. This should be clear in it’s documentation (but often isn’t). In general, this excludes many older designs from VDO and others makes from up to the mid 1990’s. Many later designs from the early 2000’s onwards will work from many different signal specs including a 12V square wave.

See the FAQ below for a lot more detailed information on rev counters and using them in Subaru powered VW conversions: