Price: from £468.33 GBP + VAT (£562)

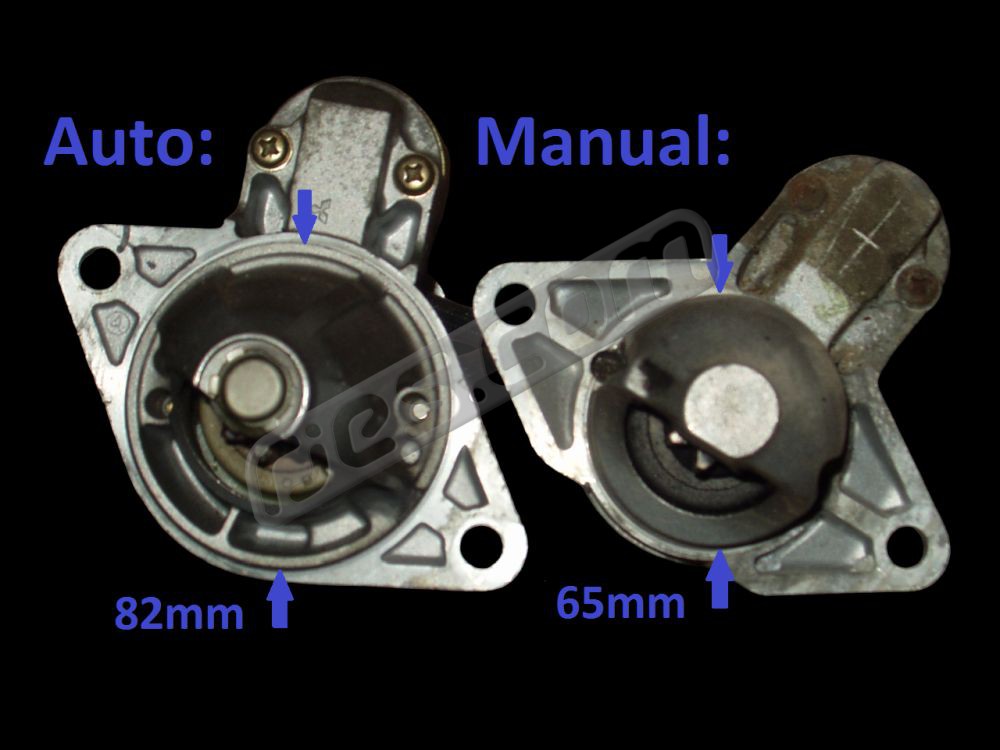

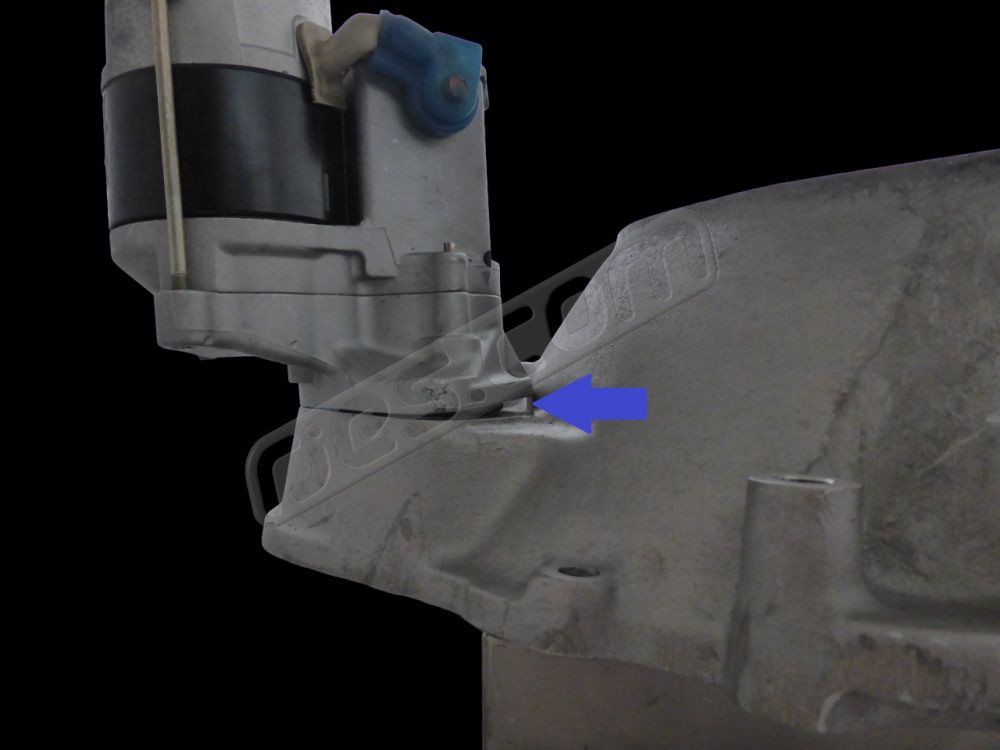

Our bell housing kits suit joining just about every Subaru EJ, EG, EZ, EE, FA and FB series Subaru engine, from manual or automatic Subaru models, to all VW 002, 091 and 094 manual transaxles. i.e. all the rear engined VW bus and Type 4 models with manual gearboxes. They do so using the Subaru flywheel, clutch and starter motor (including all the ‘pull to release’ clutch models), solving all the problems inherent to using ‘adaptor plate and flywheel’ kits with original VW bell housings. Prior to our designing them back in 2002, adaptor plate / flywheel kits were the only way to join Subaru engines to VW gearboxes, but which force you to use unsuitable clutches and starter motors.

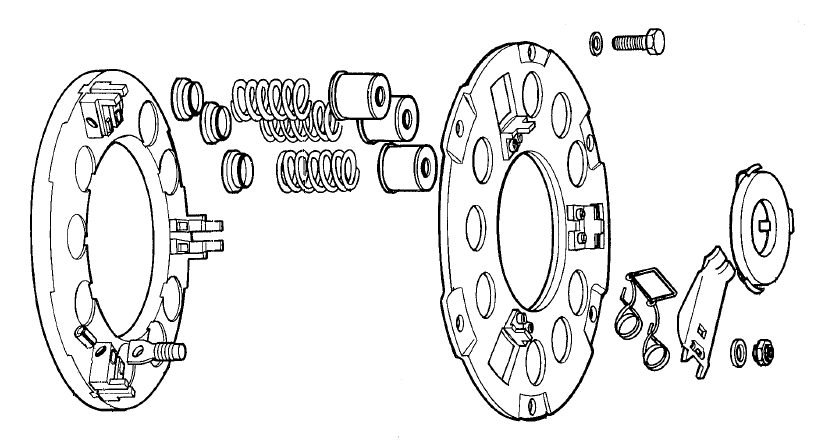

Subaru use many different clutch and flywheel types, and covering all of them with one bell housing kit is not possible, so we make versions to suit each clutch type. Most of our bell housing kits can be converted to suit other Subaru clutch types by purchasing additional parts – . i.e. without having to change the entire kit. There is a version of each bell housing kit to suit each VW gearbox input shaft type.

See The Advantages of our Bell Housings for more details.

See Bell Housing FAQ for answers to some common questions.

VW Bell Housing Kits for Subaru ‘push to release’ Clutch, Single Mass Flywheel, Normally Aspirated EJ or FA Series Engines (part numbers 800-00001 and 800-00021):

The bell housing kits required by a very large majority of customers. They suit all normal use applications with 225 – 230mm ‘push to release’ clutches’ used with the EJ series engines, with up to around 170 bhp, and use a VW 228mm clutch disc.

Designed for use with the following Subaru flywheel and clutches:

| Flywheel: | From: | To: | Induction: | Subaru models: | Engines: |

| single mass, flat faced, 268mm clutch PCD | MY90 | MY99 | normally aspirated | L, I, F | EJ20, EJ22, EJ25 |

| single mass, flat faced, 268mm clutch PCD | MY00 | MY07 | normally aspirated | I, F | EJ20, EJ22, EJ25 |

| single mass, flat faced, 268mm clutch PCD | MY00 | onwards | normally aspirated | L ** | EJ20, EJ25 |

| single mass, flat faced, 268mm clutch PCD | MY08 | MY14 * | normally aspirated | various | EJ20, EJ25 |

| single mass, flat faced, 254mm clutch PCD | MY90 | MY94 * | normally aspirated | L | EJ18 |

| single mass, flat faced, 268mm clutch PCD | MY12 | onwards | normally aspirated | GT86 / BRZ | FA20 / 4U-GSE |

The release bearing(s) and diaphragm spring centre that this bell housing kit works with are as below. No other types, including the thinner version of this bearing design are suitable (clutch parts not included):

Versions of this kit are available for both the long and short VW gearbox input shafts. The long gearbox input shaft was used in type 4 engined bays / T2’s and petrol T25 / T3 / Vanagons). They are 298mm long overall, and have a nominal 43.5mm protruding past the engine end of the clutch spline in to the pilot (or spigot) bearing. The short gearbox input shaft was used in type 1 engined bays / T2’s, diesel T25 / T3 / Vanagons and the CT 1.6 petrol engined T25 / T3 / Vanagon). They are 286mm long overall, and have a nominal 31.5mm protruding past the engine end of the clutch spline in to the pilot (or spigot) bearing.

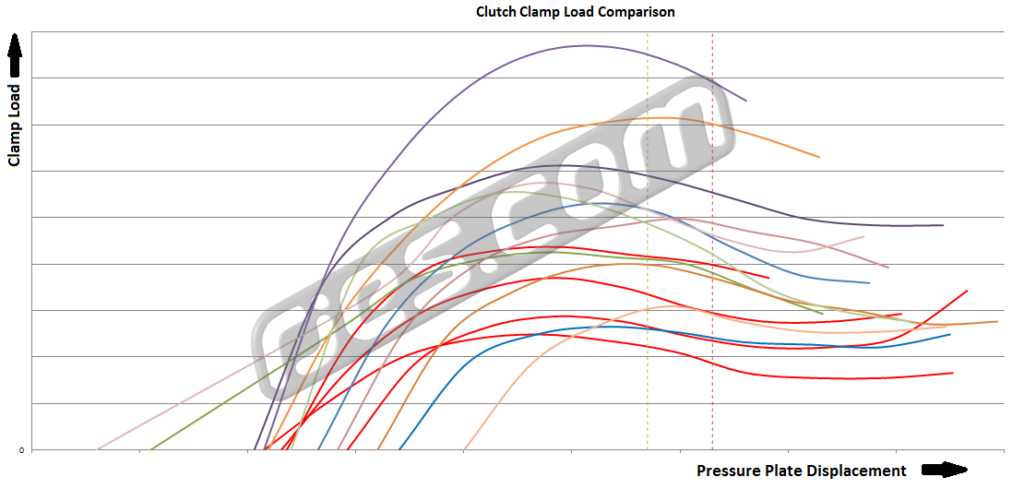

We can also do a version of these kits for use with the BRZ / GT86 230mm clutch and it’s matching flywheel, on either EJ or FA series engines. They don’t use the same flywheel as the EJ series ‘push to release’ clutches though – they use the 254mm PCD flywheel from the GT86 / BRZ with a 2mm step (which is physically interchangeable with the flywheel from the ‘push to release’ MY05 onwards low powered turbo pull to release application, but considerably lower inertia / ‘lighter’). These also use the VW 228mm clutch disc. However, note that the standard GT86 / BRZ clutch does not have a very high torque capacity – around 84% of that of the standard Subaru / Exedy EJ25 clutch, or just 73% of that of the EJ25 clutch that we stock. For almost all VW applications, you’re better off using the 268mm flat faced single mass EJ series flywheel. Far more clutches are available for them, and they were used in many more Subaru models.

If you’re interested in this kit, you may also be interested in the following associated parts:

050-00025 Clutch release shaft

800-00024 Clutch release shaft fitting kit

100-00073 Release shaft arm (hydraulic clutch)

100-00072 Release shaft arm (cable clutch)

100-00075 Return spring (cable clutch)

100-00076 Spring seat (cable clutch)

800-00053 Slave cylinder bracket (our reproduction of the VW petrol bracket)

800-00046 Bell Housing to engine bolt set – Phase I (2 bolts)

800-00062 Bell Housing to engine bolt set – Phase II (6 bolts)

040-00032 Lower engine to bell housing stud (per pair)

040-00043 Replacement input shaft oil seal

800-00021 Clutch kit (good for up to around 170 bhp in normal use applications)

100-00071 Flywheel

800-00042 Flywheel bolt set

100-00040 Flywheel cover

VW Bell Housing Kits for Subaru ‘pull to release’ Clutch, Single Mass Flywheel, Turbo EJ Series or 6 Cylinder Normally Aspirated Engines (part numbers 800-00003 and 800-00052):

Originally all of the Subaru turbo models used ‘pull to release’ clutches. Later only the higher powered models (more than about 250 bhp) used them (with the lower powered turbo models changing to a different ‘push to release’ clutch – see below for a bell housing kit for them) did. These are the bell housing kits required for the 225 and 230mm ‘pull to release’ clutches. They suit turbo or 6 cylinder normally aspirated (EZ30 or EG33) normal use applications with 225 – 230mm ‘push to release’ clutches’ and up to around 180 bhp (with the right clutch pressure plate), and use a VW 228mm clutch disc. Their clutches can only be hydraulically actuated (not cable), using the original VW T25 / T3 / Vanagon slave cylinder. Modification to the plumbing to the slave cylinder is required, as it is not used in its original position.

Subaru used many clutch kits for 200bhp to 180 bhp applications with these clutch arrangements. The most common ones used by customers are the 225mm clutch kit which suits up to 240 bhp, and the 230mm kit which suits up to 260 bhp. The 240 bhp 225mm clutch kit is very well proven in EG33 and MY00-MY03 EZ30 6 cylinder manual VW applications for normal use, when used with a suitable flat faced 254mm PDC single mass flywheel (Subaru never made manual versions of these engines).

The ‘pull to release’ clutches and their corresponding flywheel and these bell housing kits also suit some applications in VW conversions which did not originally use them, with examples being the MY00-MY03 EZ30 (no manual model was made), or normally aspirated EJ series engines in non normal use applications where a stronger clutch is required. Note there has seemed to be a belief at times, particularly in the VW Syncro world, that stronger (i.e. a higher torque capacity) = better in terms of clutches, resulting in customers fitting clutches with a far higher torque capacity than they need. In almost all cases this is a mistake, giving an excessively heavy clutch pedal with no benefit.

These kits include a new clutch release shaft, as the VW clutch release shaft cannot be used.

| Flywheel: | From: | To: | Induction: | Subaru Models: | Engines |

| single mass, flat faced, 254mm clutch PCD | MY90 | MY01 | Turbo | all | EJ20, EJ25 |

| single mass, flat faced, 254mm clutch PCD | MY02 | MY04 | Turbo | all 5 speed and / or up to about 250bhp | EJ20, EJ25 |

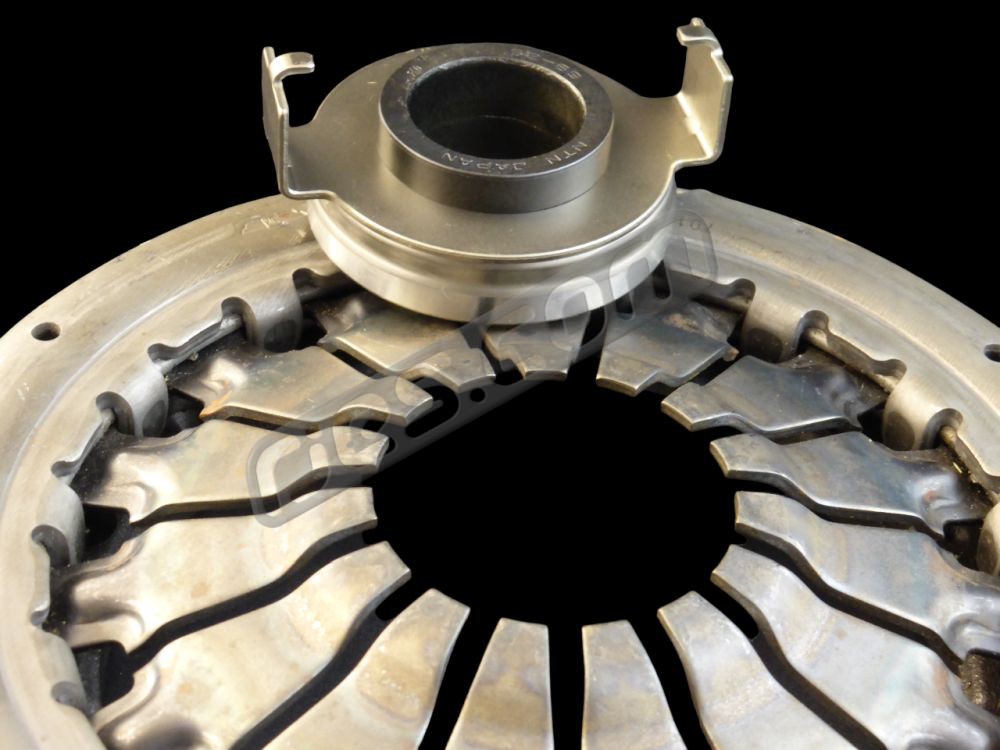

The release bearing and diaphragm spring centre that this bell housing kit works with are as below. It is not compatible with any other release bearing types (clutch parts not included):

Versions of this kit are available for both the long and short VW gearbox input shafts. The long gearbox input shaft was used in type 4 engined bays / T2’s and petrol T25 / T3 / Vanagons). They are 298mm long overall, and have a nominal 43.5mm protruding past the engine end of the clutch spline in to the pilot (or spigot) bearing. The short gearbox input shaft was used in type 1 engined bays / T2’s, diesel T25 / T3 / Vanagons and the CT 1.6 petrol engined T25 / T3 / Vanagon). They are 286mm long overall, and have a nominal 31.5mm protruding past the engine end of the clutch spline in to the pilot (or spigot) bearing.

If you’re interested in this kit, you may also be interested in the following associated parts:

800-00024 Clutch release shaft fitting kit

100-00073 Release shaft arm (hydraulic clutch)

800-00046 Bell Housing to engine bolt set – Phase I (2 bolts)

800-00062 Bell Housing to engine bolt set – Phase II (6 bolts)

040-00032 Lower engine to bell housing stud (per pair)

040-00043 Replacement input shaft oil seal

100-00042 Clutch kit, ‘pull to release’ 225mm, VW disc (good for up to around 240 bhp in normal use applications)

800-00063 Clutch kit, ‘pull to release’ 230mm, VW disc (good for up to around 280 bhp in normal use applications)

800-00042 Flywheel bolt set

100-00040 Flywheel cover

VW Bell Housing Kits for Subaru ‘push to release’ Clutch, Single Mass Flywheel, Turbo Turbo EJ Series or 6 Cylinder Normally Aspirated Engines (part number 800-00058):

Subaru introduced a new clutch arrangement for the lower powered (up to about 250 bhp) turbo models in MY05. For the first time in the turbo EJ series Subaru era, it is a ‘push to release’ clutch. However, it and it’s clutch release mechanism (and therefore bell housing kit) do not interchange with the similar normally aspirated ‘push to release’ clutch arrangement. This bell housing kit is specifically for them.

This kit also has the advantage of being able to have its clutch hydraulically or cable actuated, so will be of use if you’re using a lower powered turbo engine in an application which does not suit (or which you don’t want to convert to) a hydraulic clutch. They are not as well proven in applications such as the EZ30 or EG33 in manual VW applications as the 240 bhp 225mm ‘pull to release’ clutch is at present, but could be ideal for some niche VW applications.

These kits include a new clutch release shaft, as the VW clutch release shaft cannot be used.

The release bearing and diaphragm spring centre that this bell housing kit works with are as below. It is not compatible with any other release bearing or clutch types (clutch parts not included). Note the distinctive crank in the tips of the diaphragm spring and different release bearing:

Versions of this kit are available for both the long and short VW gearbox input shafts. The long gearbox input shaft was used in type 4 engined bays / T2’s and petrol T25 / T3 / Vanagons). They are 298mm long overall, and have a nominal 43.5mm protruding past the engine end of the clutch spline in to the pilot (or spigot) bearing. The short gearbox input shaft was used in type 1 engined bays / T2’s, diesel T25 / T3 / Vanagons and the CT 1.6 petrol engined T25 / T3 / Vanagon). They are 286mm long overall, and have a nominal 31.5mm protruding past the engine end of the clutch spline in to the pilot (or spigot) bearing.

If you’re interested in this kit, you may also be interested in the following associated parts:

050-00025 Clutch release shaft

800-00024 Clutch release shaft fitting kit

100-00073 Release shaft arm (hydraulic clutch)

100-00072 Release shaft arm (cable clutch)

100-00075 Return spring (cable clutch)

100-00076 Spring seat (cable clutch)

800-00053 Slave cylinder bracket (our reproduction of the VW petrol bracket)

800-00046 Bell Housing to engine bolt set – Phase I (2 bolts)

800-00062 Bell Housing to engine bolt set – Phase II (6 bolts)

040-00032 Lower engine to bell housing stud (per pair)

040-00043 Replacement input shaft oil seal

800-00042 Flywheel bolt set

100-00040 Flywheel cover

How to Identify the Short and Long VW Input Shafts:

The Advantages of our Bell Housings:

- No overloaded VW starter motors – an inherent and largely unavoidable problem when using ‘adaptor plate and flywheel’ kits to join Subaru engines to original VW bell housings. Note, adaptor plate and flywheel kits are your only option if you are using a type 1 gearbox, as they do not have removable bell housings.

- No overloaded VW clutches or requirement to use ‘aftermarket only’ uprated VW clutches due to there being no space in VW bell housings to fit more suitably sized clutches.

- No concentric clutch slave cylinders. A truly awful invention from a servicing point of view (they usually require replacement when changing the clutch, and cannot be serviced in any way without splitting the engine and gearbox), concentric slave cylinders only advantages are in assembly time and manufacturing cost. A conventional VW type clutch actuation via a clutch release shaft is very preferable, and also enables hydraulic or cable actuation and using the original VW actuation parts for all ‘push to release’ clutch applications (the ‘pull to release applications require hydraulic actuation, but still use the standard VW slave cylinder).

- No need for awfully engineered ‘extensions’ to the gearbox input shaft required – the shaft remains installed exactly as VW intended, with no spacers between the two shaft sections.

- Cast from and heat treated to the best specification for the application. LM25 TF (356 T6) – the same spec aluminium as used in almost all cast aluminium motorsport cylinder heads, blocks and gearbox casings.

- Three recesses cast in to make separating the engine and bell housing far easier than it is in a Subaru (it’s very difficult, as Subaru seemingly didn’t think about how to separate them while designing).

- Almost certainly the most details instructions you’ll ever see for a similar product – every detail explained, with photos of all major steps