Subaru have used many different flywheel types to suit different clutch applications in their manual models. Some aspects of the flywheels have always remained constant, such as the crank bolt pattern, the pilot bearing arrangement and the starter ring gear arrangement. Others such as as their inertia, whether the torsional vibration damping is done by the flywheel (i.e. dual mass), clutch disc (single mass) or both, and the clutch attachment geometry have changed many times. Some variants have been used for a very long time in many models, and others only briefly, and / or in only one model.

With the 1990’s Subaru models flywheels were simple, as there were only two types. Multiple part numbers for each, but two types in terms of physical interchangeability. From around MY00 onwards it gets a lot more complex.

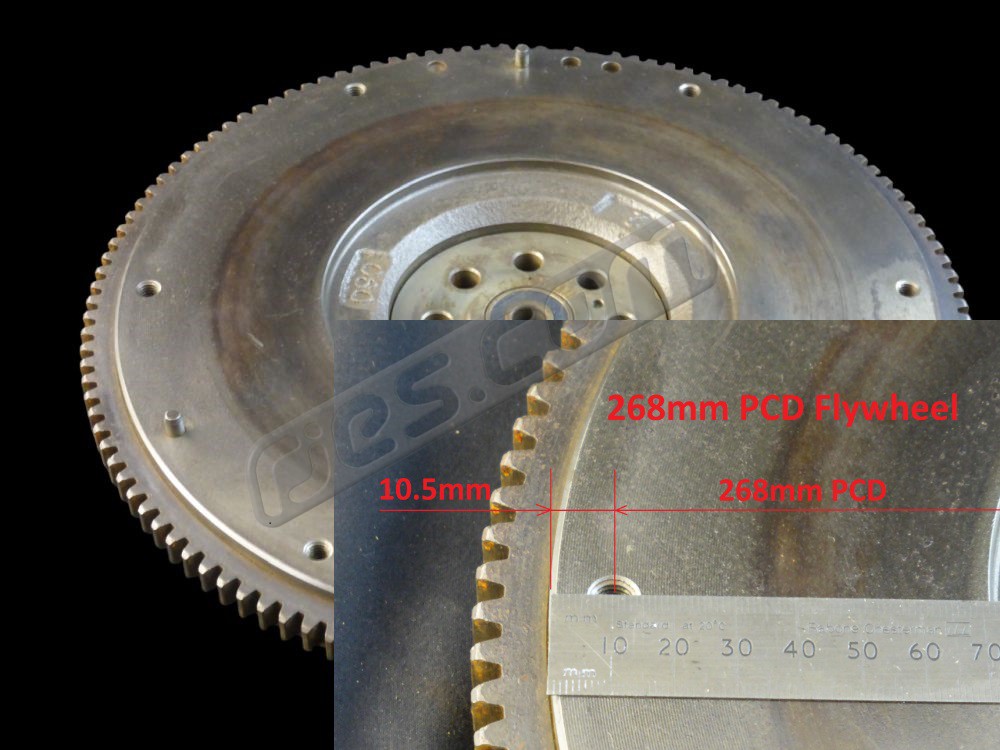

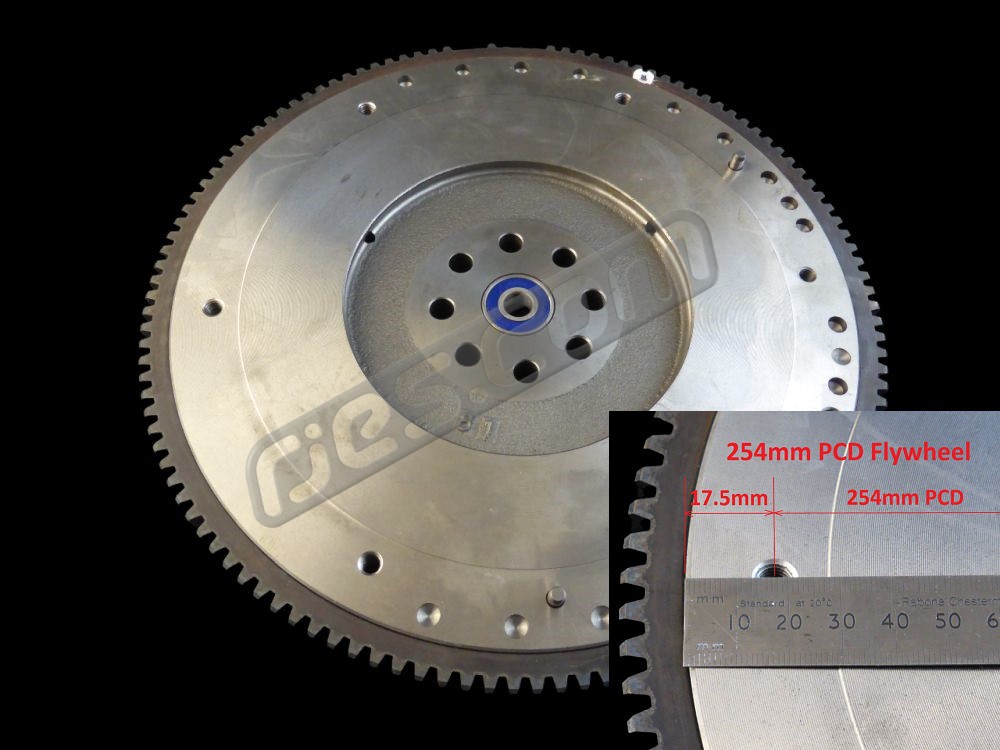

All of the Subaru flywheels used in 1990’s models were flat faced designs, where the pressure plate bolts to the same planar surface that the disc friction lining runs on. Some of them really are flat faced – with the same machining operation right across the gearbox side, and others have a very small step of around 0.2mm between the friction fave and the pressure plate bolt face. This 0.2mm step is irrelevant in terms of clutch operation. The difference between the two is the pitch circle diameter (PCD) that the pressure plate bolts and dowels are on. This and what each is used fr is explained below, and the difference is easily visible when buying flywheels once you know what you’re looking for:

‘Push to Release’ Clutch Flywheels for Normally Aspirated Applications

268mm PCD – used for all of the 1990’s normally aspirated Subaru applications with ‘push to release’ clutches (except the early EJ18 from about MY90 – MY92), and well beyond that with the same clutches in certain models. Most types have 2 clutch alignment dowels, some have 3. The same clutches fit either:

The MY90 to about MY92 EJ18 engine used a 215mm clutch with flat faced flywheel. They used a 254mm PCD which is physically interchangeable with the flywheels mentioned next for the turbo 5 speed models, but it has a much lower moment of inertia.

Both of these flywheel types were used for many years after the 1990’s too. For European / ‘rest of world’ spec models, they were usedin :

* Some, but not all MY00 – MY03 Legacy / Liberty models

‘Pull to Release’ Clutch Flywheels for Turbo Applications

Like the flywheels for the ‘push to release’ clutches, the ‘pull to release’ equivalents also all have flat faces, with some being truly flat, and others having a very small, inconsequential step (0.2mm). See above for more details.

254mm PCD – used for all of the 5 speed turbo Subaru applications up to MY04, with ‘pull to release’ clutches, and well beyond that with the same clutches in certain models. Both the 225mm and the 230mm Subaru ‘pull to release’ clutches fit the same flywheel. Most types have 2 clutch alignment dowels, some have 3. The same clutches fit either. Six speed EJ engined Subaru’s do not use these flywheels:

‘Push to Release’ Clutch Flywheels for Turbo Applications

Up to MY04 all Subaru turbo models used ‘pull to release’ clutches. For MY05 (in European / ‘rest of world’ models) they introduced a new ‘push to release’ clutch for the lower powered turbo models (up to around 250 bhp). It is not compatible with any of the previous ‘push to release’ clutch installations, as it requires a unique flywheel and release bearing. The flywheel has the same 254mm clutch PCD as the previous 5 speed turbo models, but is not flat faced. the friction face is recessed 2mm from the pressure plate bolting face:

‘Push to Release’ Clutch Flywheels for BRZ / GT86 Applications

For the new BRZ / GT86 in MY12, despite using what was effectively a Toyota gearbox with a Subaru shaped bell housing for the new FA20 engine, the BRZ / GT86 used a Subaru clutch arrangement. But one which has only one part and some geometry carried over. It used a new flywheel with the same geometry as the MY05 –> lower powered turbo ‘push to release’ clutch flywheel, with a much lower moment of inertia, and a new pressure plate. The BRZ / GT86 clutch / flywheel combination may not be the best suited to may VW conversions, for a couple of reasons – they have a relatively low torque capacity, and the lower intertia flywheels will not suit all VW bus applications well, so consider this before deciding to use them (although the flywheel inertia can be increased by using the equivalent MY05 –> lower powered turbo ‘push to release’ clutch flywheel):

‘Pull to Release’ 240mm Six Speed Flywheel for MY02 Onwards Higher Powered Turbo Applications

From MY02 onwards, when the stronger 6 speed gearbox was introduced for the higher powered turbo models such as the STi, Subaru introduced a new stronger clutch too. Bigger in diameter then any of the previous clutches at 240mm, the only part which interchanges with the earlier models is the release bearing. The flywheel is very visually different to all other Subaru flywheels, with 9 pressure plate bolts instead of the usual 6, and a 15mm step from the pressure plate bolting face to the friction face in a 15mm deep recess:

Subaru Single Mass vs Dual Mass Subaru Flywheels

Dual mass flywheels (DMF’s) in general don’t have a good reputation. This is for a few reasons:

- Because they are a service item. A single mass flywheel (SMF) in a vehicle which gets its clutch serviced correctly and which gets driven in a normal, non abusive way will often mast the life of the vehicle, but most dual mass flywheels are intended to be replaces when the clutch is worn out

- Because dual mass flywheels are much more complex than single mass, they have more failure modes. Without abusing the clutch, it is pretty difficult to damage a single mass flywheel, but the springs, dampers or other moving parts in a dual mass flywheel can fail.

- Because in many applications (including Subaru) the friction face of a dual mass flywheel is very much thinner than in an equivalent single mass flywheel, meaning is is less stiff, so less able to resist distorting if the clutch gets hotter than it should do

- Because the extra complexity of a dual mass flywheel means they are always far more expensive then single mass flywheels

….yet they have become more and more widely used by Subaru and just about all other makes since they were introduced (in MY00 for Subaru’s in Europe). Subaru have used a few different designs of dual mass flywheel, and all are a lot less versatile than many of the single mass flywheels are in terms of clutch choice. Typically Subaru used a much more limited range of clutches with the DMF’s and aftermarket clutch choice for them typically doesn’t exist – just the OEM selling their version of the genuine parts without Subaru part numbers.

There is a good argument for keeping dual mass flywheels in their OEM applications (i.e. not replacing them with single mass flywheels). However, in an aftermarket application, using a different gearbox, and often when using engines which were sold both with SMF’s and DMF’s in different models or markets for many years (as is the case with many of the more common Subaru engines fitted to VWs), using the Subaru DMF if the engine came with one makes very little sense. If the engine was from an auto, fitting a DMF makes no sense at all. You can usually buy a new SMF and clutch for far less than the cost of a new DMF. This is what we recommend you do for almost all VW engine conversions.

Petrol Subaru Valeo 230mm Dual Mass Flywheel

Used in some Legacy / Liberty models from MY00 to MY03, and all Legacy models from MY04 onwards, these were the first Subaru DMF’s:

This is a conventional dual mass flywheel, in that all of the torsional vibration damping is done by the flywheel with the disc hub being rigid.

Those who are not familiar with Subaru engines sometimes confuse these first DMF’s for an SMF. This is because they don’t look like many DMF’s do – in general mist DMF’s are more bulky than their SFM equivalents. Valeo made these DMF’s and their clutches for Subaru, and the intention seems to have been to squeeze the clutch and flywheel assembly into the same space previously occupied by the SMF and its clutch. This doesn’t seem to have been entirely successful, as they soon introduced a thinner release bearing for models with the DMF.

Diesel Subaru Sachs 240mm Dual Mass Flywheel

Used with all of the EE20 diesel engines, from MY08 onwards.

These Sachs DMF’s are a much less conventional in that both the flywheel and matching Sachs clutch disc do part of the torsional vibration damping each (i.e. the disc hub is also spring and damped). The damping properties of the disc and flywheel will be carefully matched to prevent resonance, so swapping the disc in this clutch would be asking for trouble. There is no suitable VW clutch disc that is compatible with this flywheel.

Subaru Flywheel to Crank Bolts:

All the Subaru single mass flywheels use the same bolts. They’re nice and easy to use as they have 14mm flanged hex heads. Dual mass flywheels and automatic torque converter drive plates used a few different bolt sizes, none of which match the single mass flywheels, so if you’re removing them to fit a single mass, you need new bolts too. We stock them – ours have a different hex size, but they’re the same spec.

If your engine has the Valeo dual mass flywheel and you’re removing it to fit a single mass, you’ll find removing it isn’t straight forward. The bolts for the Valeo DMF are not hex heads, they’re Torx Plus. Anyone who has not come across Torx Plus before will probably mistake them for Torx, and try to undo them with a normal Torx bit. This is a mistake, and often breaks the bolt heads (as does trying to undo them with an Allen bit). Torx Plus is a heavier duty version of Torx, and although they look very similar, they’re not interchangeable. The correct Torx Plus but size is TP50. Torx Plus bits used to be incredibly hard to get. Back in around 2003 we had to order a set from the US after not being able to find any tool brands who had them in stock in the UK. They’re easier to get now, but still not exactly common.

The other problem you’ll have if removing a Valeo DMF is that the holes in the clutch friction face do not line up with the bolts, so you can’t get the Torx Plus bit into the bolt heads square. If you don’t need to use the DMF again, you can remove the friction face from the DMF which gives perfect access to the bolts – but you’ll never get the DMF back together again. How to get the DMF apart is not immediately obvious. The friction face is held on by a circlip, but it’s very hard to see. It is in the groove highlighted by the red arrow in the picture above. Remove it and pry the friction face away from the rest of the flywheel. Once it’s removed you have perfect access to the Torx Plus bolts.