From the Euro 3 emissions requirements onwards (MY00), some of the Subaru models widely used in VW conversions have exhaust gas recirculation. In models sold in Europe, they start with the EZ30 from it’s introduction in MY00, and were on some, but not all normally aspirated EJ20 and EJ25 models by MY02 (for some reason Subaru used two different OBD II management systems on near identical engines simultaneously for a few years beginning in MY02, in the same market, one with and one without EGR). In other markets, especially the US, EGR was used earlier. EGR seems to have first been used in California spec cars, to meet the then new CARB emissions requirements from the mid 1970’s onwards – eg many mid ’70’s California spec VW models. By the time Euro 4 emissions requirements cut in around MY05, almost all Subaru enguines have EGR. Don’t just think of EGR as an emissions control system though – it’s more than that.

EGR is quite widely misunderstood. Many believe that because it replaces some of the intake charge with exhaust, it reduces the power of the engine, but that is not strictly true. At anything but wide open throttle in a petrol engine, you’re not actually using the engines full power anyway, but are forced to stick to manageable air / fuel ratios. This means that there are points in the normal running of an engine without EGR where the engine management is forced to burn more fuel than is required for the power demanded just to keep the air fuel ratio withing acceptable limits – i.e. it’s adding fuel just to prevent too lean a mixture resulting in excess temperatures.

EGR is quite a clever way to effectively make the engine run as if it has a smaller capacity under part throttle, lower power demand conditions. Instead of having to add fuel to the air to keep temperatures acceptable, it replaces some of that air with exhaust which has almost no oxygen in it, meaning that less fuel can be added without increased combustion temperatures. The reduction in fuel burned means better fuel economy, and in a system which is working properly, there is no downside to this.

The exhaust in the combustion chambers also cools the combustion, and this is how EGR improves emissions. The reduced combustion temperature results in less nitrogen oxides being created. In most or maybe all cases the reduction in NOx emissions was the primary reason for the additional cost and complexity of adding EGR, and the improved fuel economy is an added benefit.

For a much better explanation of EGR, and some simple (but rather clever) experiments which help to show what is being described, see this excellent video by Mr. DIYer https://www.youtube.com/watch?v=FrpyLvPodkc .

The video also addresses the ill-conceived ideas that many have about removing EGR on standard engines. Blocking the EGR pipe on an engine with a management system which thinks it has EGR will get rid of the fuel savings that EGR creates. It will also create error codes, and may put the engine into some kind of restricted performance mode to get you home. It may even result in the mixture going lean because the volume of the combustion chamber which should be occupied by exhaust when EGR is doing its thing will then be filled with air, although with all engines with closed loop mixture control (i.e. those with lambda sensors), the engine management will at least partially make up for this by adding more fuel.

Thanks to Mr. DIYer for creating his excellent video on EGR and being OK with us linking to it.

Another interesting way to think of EGR is as a clever way to allow petrol engines to gain some of the improved efficiency that diesel engines have:

Part of the reason that diesel engines are more efficient than petrol / gasoline engines is that they do not have throttles to control the air drawn in – the power is entirely managed by altering the amount of diesel injected, and there is effectively no downside to this, (OK, yes there is in terms of emissions, but not in terms of controlling the power the engine creates). If you ignore there being more friction in bigger engine, this means that in fuel consumption terms, a diesel running at less than full power is effectively the same as a smaller diesel engine.

The same cannot be done with petrol engines because of the fuel ratio requirements for them to run without damaging themselves. To reduce the power output of a petrol engine, both the amount of air and fuel going in to the engine has to be reduced. Even then, there is a limit to how much the fueling can be reduced before the mixture goes too lean, risking overheating and detonation. i.e. the volume of air in the cylinder will always need a minimum amount of fuel to burn without detonation.

If you can fill less than all of the cylinder volume with air when the inlet valves open, then you can safely inject less petrol without risking detonation. This is what EGR does – it replaces some of the incoming air, at times when the engine’s full power is not required, with exhaust (effectively gas with no oxygen in it), allowing the engine to run safely fueled as if it is a smaller capacity engine, just like a diesel does.

EGR and VW engine conversions

In many cases using Subaru engine models with EGR makes no difference to the work involved in installing the engines into VW’s, but there are a couple of exceptions:

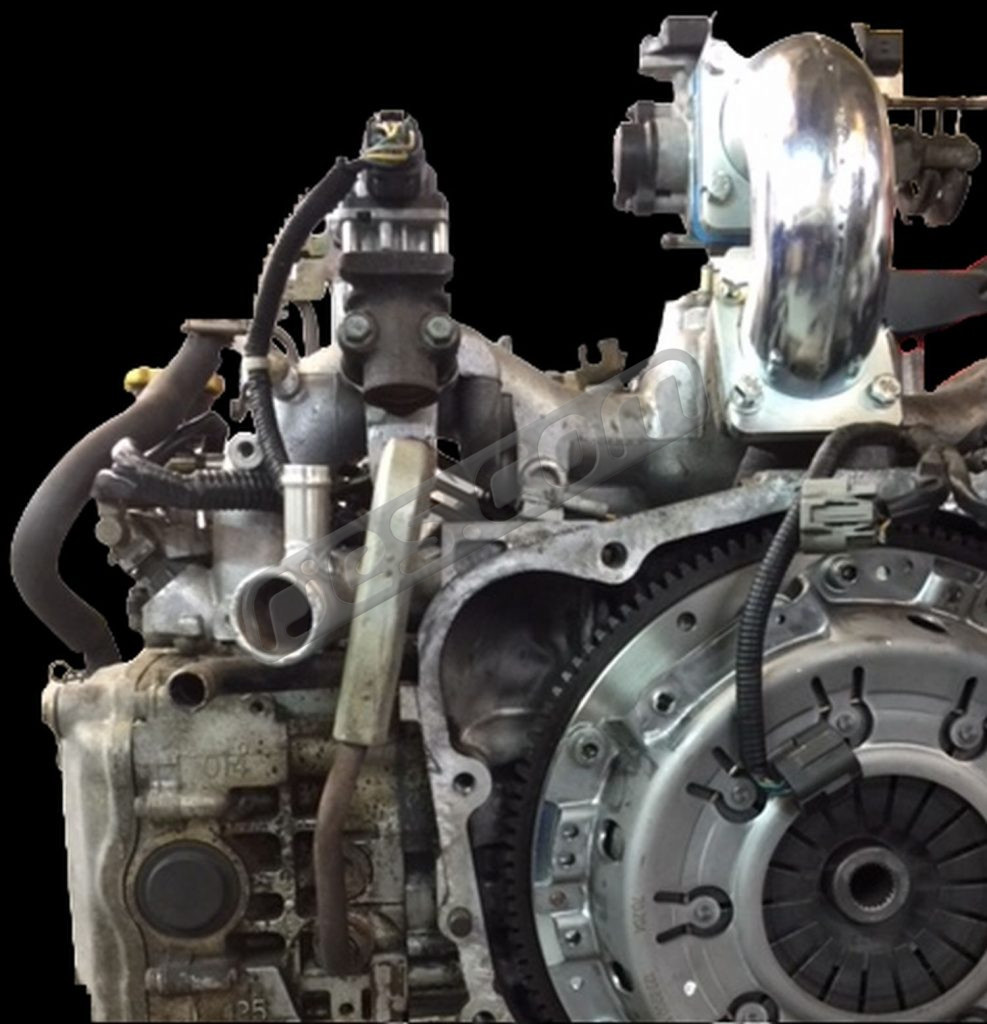

Using an EGR EJ201 or EJ251 engine with a reversed coolant manifold:

The EJ201 and EJ251 models which have EGR also have one of the later designs of coolant manifold (types D, or E, as shown on our Reversed Coolant Manifolds page). While these types can be modified to fit in reverse, but they once reversed, they only fit models without EGR.

Conversely, the original design of coolant manifold as used on n-a models from MY90 – MY01 (types A, B, or C, as shown on our Reversed Coolant Manifolds page), and turbo from MY90 – MY97, when modified to fit in reverse, will fit models with EGR, as shown below:

Using an EGR engine in a late bay / T2b:

The same ‘late bay only’ additional chassis crossmember which means the late bay is the only VW model in which the body needs modifying to fit one of out bell housings, and in which reversed coolant manifolds cannot be used also gets in the way of EGR. The vertical EGR pipe from the cylinder head to the EGR valve shown above also sticks out beyond the engine to gearbox joining face by about 40mm. In all other VW models this is not a problem, but in a late bay, the pipe fouls on the extra crossmember next to the starter motor. The picture below shows the starter motor are of the bell housing from below, with the extra crossmember above it:

For this reason it is best to use one of the engines without EGR in late bays.